+ ECAM Lyon – Applied research center

Presentation

The role of ECAM Lyon’s research teams is to act as an engineering resource centre for enterprises, for both applied research studies and activities more involved in transferring technologies.

These studies can be experimental and/or theoretical, though they also cover the design of mechanical and electronic systems.

- 22 actors in research (9.5 full-time)

- 10 teacher-researchers

- 7 PhD students,

- 1 post-doctoral student

- 4 engineer and technicians

- 10 international publications /year

- 10 conferences / year

- 1 patent/year

- TO €412 K

See its technological skills

Contacts

ECAM Lyon

40 Montée Saint Barthélémy 69321 Lyon Cedex 05

Area(s) of search

Projects

ADAPTED KNOWHOW

Aimed at the Aeronautics, Automobile, Mechanical, Materials and Processes, Energy & Environment and Railway markets, the laboratory’s multidisciplinary teams cover a wide range of competences in mechanics, materials science, and energy, electrical and automation engineering.

- Energy efficiency of systems, machines and other processes

- Energy modelling (coupling heat transfers and power losses) of energy conversion systems: mechanical power transmissions, electric systems.

- Advanced regulation of energy systems (thermodynamic machines, energy storage systems, etc.).

- Microstructural modification of materials and its influence on the physical properties and mechanical resistance of parts:

- Production of parts by powder injection moulding (metal and ceramic parts).

- Thermochemical treatment under controlled atmospheres (cementation, nitriding, carbonitriding).

TECHNICAL RESOURCES

The Energy and Materials & Structures sectors use the following simulation software applications: ANSYS, FLUENT, AMESIM, MATLAB-SIMULINK, DSPACE and VISSIM, closely linked with advanced experiments that rely on leading edge equipment such as:

- Test benches for characterising no load losses, the lubrication and thermal behaviour of gear systems.

- Regulation systems, including a bench equipped with heat exchangers and an air treatment unit.

- Platform for studying the fabrication of parts by powder injection (development of master batches): mixer, rheometer, injection moulding press, etc.

- Sintering furnace and thermochemical treatments under controlled atmospheres.

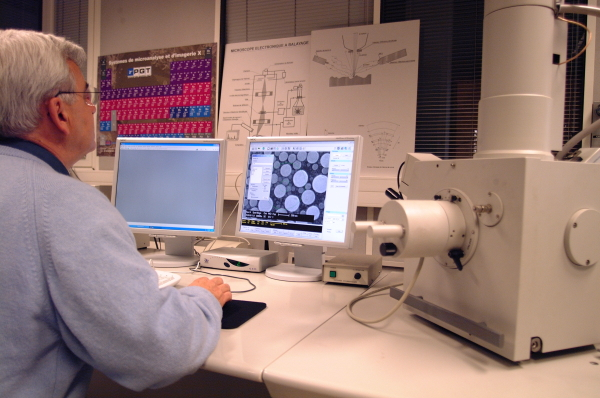

- Material characterisation: ESM, thermogravimetric analysis, curve detector for X-ray diffraction, mechanical tests, etc.

REPUTATION & DISTINCTIONS

ECAM’s national and international reputation allows its teams to participate in numerous national and European projects: Institut Carnot Ingénierie@Lyon, Fond Unique Interministériel (FUI): BIOPIM [2006-2009], PLASTRONICS [2011-2014], TECHNYMAT [2013-2016], REDHV+ [2014-2017], in the clusters LUTB, Plastipolis, Minalogic, etc. and publish in the most prestigious scientific journals.

The laboratory jointly organises reputed congresses such as the International Gear Conference 2014, the Congrès Français de Mécanique 2015, and others, and organises the Prix FEST’INNOV every year. 24H non-stop innovation events bring together students, engineers and industrial enterprises to develop innovative solutions for real technical problems encountered by enterprises.

PARTNERS

ECAM Lyon’s researchers maintain strong ties with the business community, including major groups like DANFOSS, EDF, EMERSON, GDF SUEZ, IVECO, NTN-SNR, PSA PEUGEOT CITROEN, RADIALL, SAFRAN, SCHNEIDER-ELECTRIC, TOTAL, VOLVO, etc., SMBs such as BMI, GREENMOT, HEVATECH, NIDEC ASI, SESAME PHARMA, STEELMAG, VELECTA PARAMOUNT, etc., and very small enterprises like FLUID’PLANET, PK-ENR and TECHTEAM, by approaching their research activities closer to the concerns of their industrial partners.

Internationally, they have developed strong research collaborations with Cranfield University (United Kingdom), Lodz University of Technology (Poland), Manhattan College (USA), Pontifica Universitad Catolica Del PERU (Lima – Peru), and Sherbrooke University (Canada).

The role of ECAM Lyon’s research teams is to act as an engineering resource centre for enterprises, for both applied research studies and activities more involved in transferring technologies.

The role of ECAM Lyon’s research teams is to act as an engineering resource centre for enterprises, for both applied research studies and activities more involved in transferring technologies.